Rail Car Unloaders

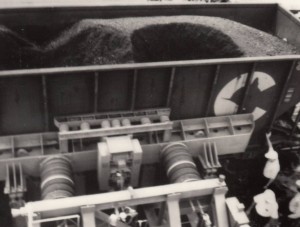

The largest Rail Car Discharger. It is used to unload a Unitrain of 100 Aluminum or Steel Cars in 4 hours or less. For faster unloading, such as ship loading at terminals, two or three large Dischargers are used to simultaneously unload the Cars.

Kinergy Rail Car Unloaders

The patented Kinergy Vibrating Rail Car Discharger has been an industry leader for over 30 years for unloading bottom dump rail cars. The reason is our engineers are innovators in the specialized field of Induced Vertical Flow. As a result of their continuous improvement of the Kinergy Vibratory Rail Car Unloaders, they can now accommodate the fast unloading of both the modern aluminum and steel rail cars. No competitor can boast as much experience with this kind of bottom dump Rail Car Unloader.

In addition to the two models shown, Kinergy has intermediate size Dischargers that are used for other applications.

The Rail Car Discharger is shipped as a complete assembly. It is permanently installed alongside the track.

Rail car damage is virtually eliminated. The operating sound levels are usually less than 90 dBA while the car is more than half full. When it approaches the empty condition, the sound level will momentarily rise to about 100 dBA. The operating sound level could be slightly higher if the unit is enclosed in a building or if the car has been previously damaged.

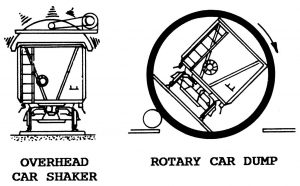

When Unitrains are being unloaded, the Kinergy Rail Car Discharger will achieve the emptying of 100 cars in four hours. While these results can also be accomplished with Rotary Car Dumpers, Kinergy Rail Car Unloaders have the significant features of low installation cost and low operating cost. More specifically, the Kinergy Rail Car Unloader can be purchased, installed, and operated for a fraction of the cost of a Rotary Car Dumper and only requires one operator.

Kinergy’s complete line of Rail Car Dischargers enable an efficient and cost effective solution for our customer’s rail car unloading needs.

Design Features of Kinergy Rail Car Unloaders

Kinergy has the most advanced vibratory machine technology available. Our designs include the following:

• Many Models: Kinergy offers a full line of Vibratory Rail Car Unloaders to suit our customer’s needs. Available from multi-positioned smaller units to single-positioned larger Unloaders that are designed to unload a Unitrain in four hours.

• Durability: Kinergy Vibrating Rail Car Unloaders are built to last. This provides our customers with experience and reliability in this state-of-the-art vibratory technology.

• Minimal Maintenance: Our units have the added benefit of very low maintenance costs. Each part is purposely designed for vibratory use, which means they will have a very long service life.

• Lower Operating Costs: The labor cost savings is significant when using Kinergy’s Rail Car Unloaders. Only one operator is required. When unloading, the Unloader is only vibrated in brief spurts.

• Versatile Applications: The Kinergy Rail Car Unloader can lower contamination and increase productivity when used to cleanse the internal surfaces of any clinging dust or tailing retained from the previously loading cars.

• Easy Installation and Start-Up: The Kinergy Rail Car Unloader is shipped as a complete assembly that is pneumatically pre-piped and electrically pre-wired. The complete installation is usually accomplished in less than one day.

• Reduced Sound Levels: Reduced sound levels are another benefit of the Vibrating Kinergy Rail Car Unloader. When the rail car is full or near full, the Unloaders will have an operating noise level of less than 85 dBA. As the contents in the car are unloaded, the short spurts of vibratory action of a near empty car could approach 100 dBA.

Kinergy’s engineers are the experts of Induced Vertical Flow. To learn more about Kinergy’s Vibrating Rail Car Unloaders, please contact us at 502.366.5685 or download Kinergy’s descriptive Bulletin KRCD-1 entitled “Unloading Bottom Dump Cars with the Rail Car Discharger”.