Fill Containers

Kinergy Filling Containers

The vibratory machines to accomplish the Densification of Containers are Tables, Activators, Mold Compactors, and the Vertical Face. All these units vibrate very quietly with minimal maintenance. Unlike Rail Car Densifiers, the density doesn’t have a limit. The goal in these applications is usually to load the container with more weight or to minimize its volumetric size.

I. Vibrating Tables

These units are used to better fill paperboard boxes, sacks, wooden crates, and reusable containers that are either flexible or rigid. The container is placed on the top surface of the Vibrating Table. The vibration can be applied at any time during its loading. Quite often, the container is vibrated when it is one-half to three-fourths full and continues until it is filled.

Various “table top” designs are available. One includes a series of parallel vertical bars that are spaced apart so they can pass up through the rollers of a Conveyor. This lifts the container above the rollers to permit it to be vibrated. Air mounts are normally used to make the “table top” move up and down, and they also serve as vibration isolators.

Densifying Tables are available in various sizes. They range from a nominal 2’ x 2’, to as large as 12’ x 12’, but they seldom exceed 6’ x 6’. They vibrate at frequencies ranging from 1140 to 3420 CPM with the higher CPM being the most popular. The stroke is manually adjustable by de-energizing the unit and changing the amount of rotating eccentric weights installed on the vibratory motor. Since the force of gravity is assisting, the vibratory drive is of the “Single Input” or Brute Force type. If an adjustable vibratory output is needed, the Kinergy Drive System can be provided. It can change the vibratory action by varying the electrical frequency of the power supply to the vibratory motor. Operating sound levels are usually less than 80 dBA.

II. Activators

When rigid type “reusable” containers are being filled, the Activator can be used to accomplish the densifying. It is designed to accommodate the specific container to be filled. Ordinarily they are square or circular in shape. The container is lowered down into the Activator by means of a forklift or hoist. Round rubber rollers guide the container down into the Activator and its base supports its bottom side. Once inserted into the Activator, it is vibrated while it is being filled. After the container is densified, it is lifted from the Activator and replaced with an empty one for filling.

No manual effort is required to fix the container to the Activator. It is simply dropped into and lifted from the vibratory unit.

Activators are available in various sizes to accommodate the configuration of the reusable container. The vibratory action is essentially in the horizontal plane at a frequency that is usually 1710 CPM. The vibratory stroke is adjusted by changing the amount of eccentric weights on the vibratory excitor. Since the force of gravity is doing most of the work, these units will almost always utilize the “Single Input” or Brute Force type of vibratory drive. The operating sound level is normally less than 80 dBA. Provided they are in reasonably good condition, the applied vibration is virtually free of any damage to the container.

III. Vertical Face

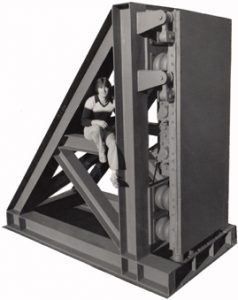

When the containers or molds are relatively large and much heavier with loaded weights in excess of 10 tons, the Vertical Face type of Densifier should be considered. The large container and heavy container is lifted and suspended by an overhead type crane. In turn, it presses the filled container against the vertical, vibrating face. Consequently, the vibration transmitted to the container densifies its contents.

The Vertical Face type of Densifier has the advantage of reducing the cost of densifying when compared to a large Vibrating Table or Mold Compactor that would vibrate the same container from its underside. Two vibratory excitors that turn eccentric weights generate a horizontal, linear stroke action to the Vertical Face. The reaction truss supports the vibrating member by rubber bushed links across the top and steel coil compression springs along the bottom. The resilient springs mounted behind the Vertical Face absorb any lateral impact of the container being vibrated. The contact “face” plate of the unit is replaceable. It has a layer of rubber behind its metal surface to make it operate at about 80 dBA, which is quiet for this type of application.

These units are available for vibrating total weights from 5 to 100 tons. Contact faces vary from 3’ x 3’ to 4’ x 10’, and they usually vibrate at 1140 CPM. They represent the best bargain as compared to alternate methods of densifying very large, heavy containers.

To learn more about Densification, call Kinergy at 502.366.5685 or download Kinergy’s descriptive Bulletin KID-1 entitled “Induced Densifying”.